Today we are going to build a Linear Optimization Model with binary constraints. What that means is that some of our decision variables are going to be restricted to 0 or 1 as possibilities.

This example is more complicated than earlier lessons, so I have included a fully filled out Excel file for you to follow along with. You can download the Excel file here: ModelBuild

Let’s start with the problem:

You have been hired by a company that builds airplane model kits. They currently produce 5 types of models – F-16’s, F-18’s, A-10’s, B-2’s, and B-52’s. They want you to help them maximize their profits.

They have provided you with the following production information.

The Minimum production may need a little explanation. Setting up the equipment to build a particular model has an expense built in. To cover that expense, you need to commit to building at least the value found in the minimum production row. If you can’t meet this level of production, we are not going to build any of this model.

We have also been given our available resources:

So now on to our decision variables. For each model, we have to first decide whether or not to produce. Remember, if we can’t produce our minimum amount for a particular model, we can’t produce any of that model.

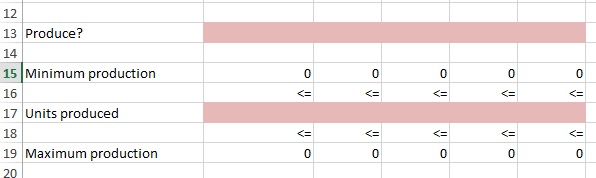

So our Produce? decision variables are going to be either 1 (produce) or 0 (don’t produce)

Now our Minimum production row is a simple formula= Minimum production from row 7 above * your 1 or 0 from Produce? I have placed a 1 in the first column of our Produce? row to demonstrate below.

Skip Units produced for now. Look at Maximum produced. This formula is simply the 1 or 0 from our Produce? row * 9999. I choose 9999 at random as I know we will never exceed this limit in our example. In other models, you may need a larger number.

Now Units produced is our second decision variable. This variable needs to sit in between Minimum production and Maximum production.

Note that if our Produce? variable is 0 (don’t build) Maximum production will be 0 (Produce? * 9999= 0) . Since Units produced needs to be less than or equal to Maximum production, we cannot produce any units.

Second, since if we decide to build (1), our Minimum production will come from our given values in blue. So our Units produced will need to be greater than or equal to the Minimum production.

Now lets set our Resource used using SUMPRODUCT()

Press Time

Grams Plastic

Finally, we need to set our Result cell – We do this using Sumproduct()

Now we can set up our solver.

- Objective – Profit cell

- Changing cells – our pink rows – note you separate the two rows with a comma

- Set our Produce? row to binary (see second picture below)

- Set Units produced to >= Minimum production

- Set Units produced to <= Maximum production

- Set Press Time Resource used <= Resource available

- Set Grams Plastic Resource used <= Resource available

Finally make sure you are set to Simplex LP and hit Solve